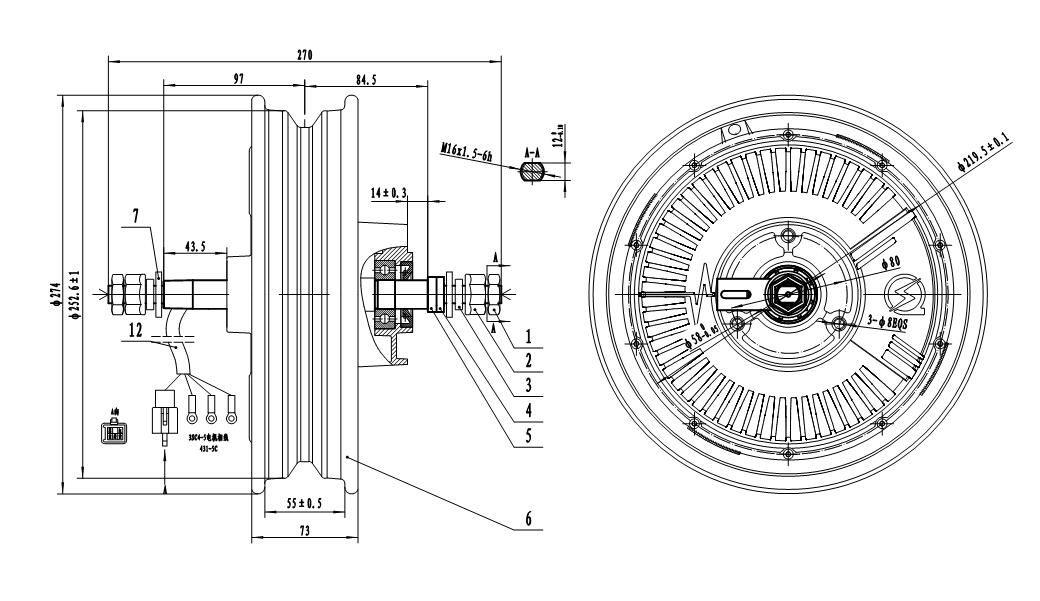

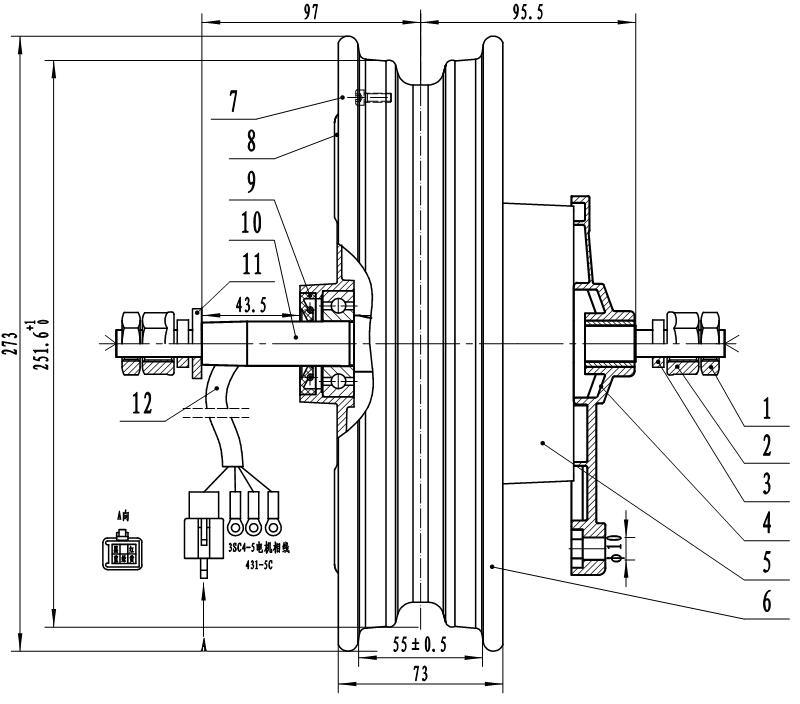

QS212 10inch E-Scooter In-Wheel Hub Motor(40H) 1500W V1 Type

Motor Specification:

1. Motor Type: BLDC Hub Motor with Permanent Magnets

2. Motor design: Double axle out with 10inch rim

3. Rim size and material:2.15-10 Iron rim

4. Matching Tire: 3.0-10, 3.5-10

5. Magnet Height: 40MM

6. Pole Pairs: 23 pairs

7. Rated Power: 1500W

8. Max Power: 2500W

9. Rated Voltage: 48V/60V/72V

10. Speed: 45km/h (30-55km/h can be customized)

11. Max No-load RPM: 700RPM

12. Max Torque: 105N.M

13. Max Efficiency: 89%

14. Max current:40A

15. Brake type: Disc brake or Drum brake(Optional)

16. Rear Fork width for installation: 200mm

17. Cross Section of Phase wire: 4 mm2

18. Axle thread:M12

19. Hall sensor phasing angle: 120 degree

20. Type of Sensor: Hall Sensor(3pcs)

21. Max. Working Temperature: 70 degree, Peak 120 degree

22. Cooling method:Air cooling

23. Waterproof Grade: IP66

24. N.W./ G..W. : 11kgs / 12kgs

Precautions for use

1. The motor is strictly forbidden to carry with it, and it is strictly prohibited to pull the lead of the motor.

2. When installing the tire, you must be careful, handle it lightly to avoid scratches or excessive force resulting in the motor hub, end cap, electric

Damage of crankshaft and lead wire.

3. All the phase wires and the terminals of the Hall element must ensure well connect, and there must be no looseness, otherwise the motor and controller may be burned. It is strictly forbidden to connect reversely or wrongly, otherwise it will cause permanent damage to the motor.

4. A controller that matches the motor or a controller recommended by the manufacturer must be used to ensure the reliability of the motor

5 It is forbidden to disassemble the motor, change the structure, refit, etc., otherwise the warranty will be invalid, and the unpredictable

Security incident!

6. The installation of the motor and the flat fork must be firm and reliable, and the fixing screws of the shaft must be tightened without any looseness.

Name: Robert Chen

Mobile:

Tel:0086-13456357532

Whatsapp:0086-15857348767

Email:info@qs-motor.com

Add:NO.2555 Shugang Road, Luqiao Dist., Taizhou, Zhejiang, China 318058